In the beginning

The following facts and stories around the development of the iron ore industry and the following steamshipping thereof, have been derived from the book: "Leven en bedrijf van Gerhard Moritz Roentgen, grondvester van de Nederlandse stoomboot-maatschappij" (“Life and business of Gerhard Moritz Roentgen, founder of the Dutch Steamship-Enterprises”) by Dr. M.G. de Boer, published by the Enterprise for ship and construction building “Fijenoord” in the occasion of her 100th anniversary in November 10th 1923.

The emerging of a steam era

In 1690 already the Frenchman Denis Papin invented the first piston steam engine and presented a concept for a steam boat that same year, turning on 4 cylinders. In 1695 he connected his machine to a rowing boat, enabling him to proceed against the wind.

With the improvements, achieved by the Scottish engineer James Watt in 1769, the efficiency of the engines was increased as from barely 1 to 19%. The modern steam engine was a fact. The evolutions of the industrial revolution followed eachothers soonest. In 1777 a steam engine was placed in a mine in Cornwall.

The American Robert Fulton created the first steam boat, which proceeded on the Seine in France in 1803. The concept was not succeeding in Europe that time, whererafter he created the “Clermont” in America, which in 1807 proceeded over the Hudson from Albany to New York.

Developments in iron

The steam ships were build for the transport of goods and passengers over the rivers. The reliability and speed of the coal fired boats appeared to have big advantages above sail ships and pulling boats. The steam ships were, same as the sail ships, made of wood and did have quite some rigging.

The developments in the iron industry was an additional

impuls for namely the Dutch Navy Officer and construction engineer

Gerhard

Moritz Roentgen who did arrange for further developing of steam

ships made of iron. In 1821 as an assignment of King Willem I he

studied the way of forging and work on iron in England, especially how

the iron ore could be made as unalloyed as possible and how the various

ovens (blast furnaces, cupola furnaces, reverbere furnaces and roller

machines) had to be arranged for the melting of the ore. The British

quality was so much better that the iron industry in Belgium stayed

energetic only that time because high excise duties had to be paid on

imported ore.

The developments in the iron industry was an additional

impuls for namely the Dutch Navy Officer and construction engineer

Gerhard

Moritz Roentgen who did arrange for further developing of steam

ships made of iron. In 1821 as an assignment of King Willem I he

studied the way of forging and work on iron in England, especially how

the iron ore could be made as unalloyed as possible and how the various

ovens (blast furnaces, cupola furnaces, reverbere furnaces and roller

machines) had to be arranged for the melting of the ore. The British

quality was so much better that the iron industry in Belgium stayed

energetic only that time because high excise duties had to be paid on

imported ore.

He visited the factories around Birmingham and Staffordshire. Not to be noticed too much he did not carry a size-stick, but he brought a specially purchased pocket knife with calibration on it.

Tip: the open air museum in Dudley: ‘The Blackcountry Museum’ gives a detailed reflection of the life and working in that district.

Roentgen discovered that the English ore was of another composition than the used in The Netherlands. In England they used the so-called “clay ironstone”, a ferrous clay layer, what was found in many coal mines and what was not required to purify.

With this fact in 1823 it was searched for in Belgium to similar clay layers and found indeed, in Luik, Mons and Charleroi. Even considerable quantities were found and good valuable coal (sofar the furnaces for melting were fired on charcoal), so that the casted iron could be delivered for about 35 guilder (16 euro) per 1000 Dutch pounds. He was about to make a start with a new model coal fired blast furnace, with an individual from Luik, Cockerill, who was a capable machine builder, and David Mushett from Coleford (GB), a skilful iron producer.

Roentgen anticipated that the iron industry did have the future: the wood would replace more and more by iron and blacksmith’s shops would be as numerous as carpentry shops. He did see already in England cranes of iron, a bridge and a canal in a iron aquaduct. He expected that iron pipes will be used for the gas lighting and that ships will not be made from not much durable wood, but of iron. And that steam ships would be used for the voyages to the Indies. He anticipated that:

“Shipping will undergo a change, bigger than with the change from rowing to sail ships, and the influence on it to the richdom power and greatness of the nations, the one is adopting this at first, will be on that in proportion and appear to be only feasible with the help of the English way of organised iron works”

On his request he was dismissed honourable from the Navy, in order that he could actively work on building the first Dutch steam ship the “Nederlander”. During the fall of 1822 already he was closely involved in founding the “Nederlandsche Stoomboot Maatschappij” (Dutch Steamship Company).

Developments in (steam)shipping

Meanwhile the engines on land had been working much more efficient. Where in Europe three quarters of the coal remained unused, the coal consumption in North America was reduced to 50 percent, due the use of “high expansion”. Roentgen wanted to use this on ship’s engines as well. By replacing a now 100 hp engine by one of 500 hp, one should be able to round the world with “120 last” of coal.

In view of his Navy history it was not surprising that he proposed to build three types of ships, of which the abilities in case of war should be useful:

- Steamtugs, as well as for inland as well as for seagoing. Excisting ships could be towed to Den Helder and Hellevoetsluis and outbound, so that these were no longer dependent of favourable weather circumstances. Now they had to wait for weeks sometimes. The large seagoing steamtugs should be 50 el in length, 8 el in width and 3 to 3.5 el draught, with a power of 400 to 500 Hp. A steamtug like that should cost 280.000 to 320.000 guilders. A smaller variant, till 80 hp, should be suitable for river navigation and cost 130.000 guilders.

- Excisting (wooden) warships could be provided with a steam engine, so that these were be useful as a ram ship. A very heavy gun that would be able to shoot ammunition of 500 pound or bombs of 300 pounds with a diameter of 5 palmen, could be placed on the foreship. With the rudder to aim and a adjusting screw for elevation the whole ship should function as afuit. In addition it could be provided with a strong knob or ram, so that it would be able to destroy enemy warships. The paddle wheels should be attached in the vessel or under water to reduce the vulnerability. Such a ship could be employed with a blockade as well; it should be able to proceed to IndiŽ, as were the seas covered with pirates.

- New to be build armour ships should reach a speed of 12 to 16 knots, should be able to go against the strongest currents, could turn into any direction and take any position, what should especially be an advantage during calm weather. Such a ship should be 70 el long, 10 el width and a draught of 5 el. The battery deck should be 4 el above waterline. It should be provided with 4 or 5 low masts, 4 engines, 3 boilers and 4 paddle wheels. The costs were estimated around 600.000 guilders.

River steamboats

Since local authorities still struggled with prejudices around safety of steamboats, in 1822 an admission was applied for to the King for a steamship line between Rotterdam and Antwerp.

Traveling by steamboat was outlined as quite comfortable, especially comparing to travelling by coach. According to Roentgen the advantages were countless:

“ In a coach one sit in a cabinet of less than 2 cubic el, locked up with three or more travellers; if one will breath fresh air, depends most of the time of the mood of the fellow travelers; big discomfort is suffered in the pose of the body; only seldom one can change his once setted pose of the body; only little one can change his once setted pose of the feet again depending of the fellow travellers; reading is more often than not impossible. In a steamboat one has the choice between two or more rooms; on deck one has a large promenade to move himself, sometimes 25 el long and 7 el wide, provided with benches, so that, while enjoying the beautiness of the landscape, can rest. One is not loosing time during lunch; the steamboat is proceeding always, even during the night; one is as in a self moving, good guest house."

Initially the required engines should be purchased abroad, but to improve the national employment, the engines should be build in own management. The assignment for the “Nederlander” was granted.

Two steam engines of 20 hp were purchased from Maudsley in London, the hull was build at weduwe J. Hoogendijk in Capelle a/d Ijssel. The first trial to Antwerp, on 31st of May 1823, did not pass successful. Due to bad gaskets too much steam was leaking, so that at Bruinisse one was turning back. A few weeks later the deficiencies were rectified and the “Nederlander” was proceeding to Antwerp after all. Whereof a speed of 9 miles were achieved. (One watch took 4 hours, the reached speed was more than 4 km per hour).

With this success more admissions were applied for (and granted) for dilegence-services to be carried out with a steamboat:

- Antwerpen – Brussel

- Rotterdam – Den Haag

- Rotterdam – Veere

- Rotterdam – Nijmegen

- Rotterdam – Arnhem

- Rotterdam – Den Bosch

- Amsterdam – Harlingen

- Amsterdam – de Lemmer

- Amsterdam – Harderwijk

Quotations were requested for building of new ships and the orders were coming in. The “Nederlander” was, as agreed, decommisioned so that good drawings could be made of the engine parts.

The steamboats, “Stad Antwerpen”, “Stad Nijmegen” en “de Zeeuw” were completed in the course of 1824. With “de Zeeuw” so much experience was gained during a heavy voyage over the Midden-Rijn through Germany, that the next chapter could be written.

Steamtugs

Basically this idea was not new, because this application was used already in the engines of Woolf as well. But here both pistons were moved by the steam in the same direction simultaneously, while in the engine of Roentgen the pistons were moving in perpendicular directions of eachother. As from the high pressure cylinder the steam was ending in a so-called “receiver”. From here the steam was directed further to the low pressure cylinder. In doing so the possibility was created for smoothly running ahead and astern, an essential feature for a steamtug.

Initially the “Hercules” should consume 800 to 900 Dutch pounds of coal to reach 160 hp. With the innovated construction 400 pounds should be sufficient. With 500 pounds could 200 hp and with 650 pounds probably even 240 hp be reached.

In 1829 this first “Hercules” was commisioned as tugboat of the to passenger yaught converted “Agrippina”.

With steamships sailing for IndiŽ

In 1823 another order of the frehsly founded steamship company fell part of. The ships which were trading to IndiŽ were plaqued by robbers and pirates regularly. That’s why the minister of Colonial affairs requested for a pair of crafts to be used for chasing pirate boats. These should have a small draught, because robbers were often hiding in shallow estuaries.

Roentgen proposed to build a tall ship that should sail to IndiŽ on it’s own propulsed by sails and by steam power. A second, smaller ship should be as a prefab transported by a sailship to IndiŽ. Under the protection of the tall ship, the smaller one could chase the pirates.

By building the Pylades the tallest ship was started. In 1834 an order for two smaller boats followed, whith a required draught of 3.5 and 2 feet only and to be equipped with compound engines, as used on the “Hercules”. At the end of 1834 the Pylades was completed, but the delivery did not develop as planned.

Because the winter season was nearing a trial was cancelled and it departed from Rotterdam on 29th of December. In those times the route to open sea was not as straight as it is nowadays. The ship proceeded through the Oude Maas to the Dordtsche Kil and was grounded of short duration due to a pilot. On January 2nd 1835 the ship departed from ‘s Gravendeel going to sea following the Goereesche Gat, of where it reached open waters close to 14.30.

The weather was good at that moment, but the captain was informed a few hours later however because the ship was flooding. There was pumped immediately, the bottom of the ship and the valves were checked, but nothing alarming was found. One thought to able to withstand the small leakages with the pumps standby.

Unfortunately the water was rising rather quickly and the pilot, who disembarked the ship earlier, was called back. The lights were extinguised by the water and when the deck was even with the water the ship was abandoned. The ship sank at 11.00 pm and during roll call it appeared that a stoker was missing….

The “Pylades” was situated 7 fathoms deep and during low tide the funnel was visible. The ship was silting very fast. On January 26th the ship was covered with sand completely, after when a longtime case with the insuring parties followed.

Ocean steam shipping

Around 1838 the emigration to North America was commencing and it became profitable to build ocean worthy steamships. In 1819 already the first steamship, the “Savannah”, partly sailing, partly steaming, crossed the ocean. The favourable results of the passage in 1836 of the “Sirius” and the “Great Western”, owned by the “Brittish Steam Navigation Company” and the “Great Western Steamship Company of Bristol” respectively, showed that ocean steaming had the future.

More iron

The ship-owners decided to build new ships made of iron completely in on or around 1840: the fully iron Zuiderzee steamboat “Admiraal Kinsbergen” was steaming with 60 hp only and overtaking the recent build “Willem I” powered by 140 hp.

The excisting steamtugs did require maintenance meanwhile. Also there it was decided to replace the wooden made hulls by iron ones, also given to the fact that the first “Hercules” was heavily damaged and sunk after a collision at Pernis.

Better engines

|

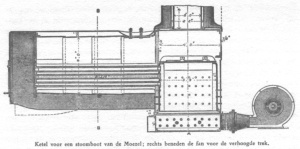

Boiler for a Moezel steamboat. Right under the fan for forced ventilation.Click on the photo for an enlargement |

Roentgen stayed interested in the development of steam engines:

- An improved arrangement of the paddle wheels, as a result of which the ship was proceeding more quiet and faster.

- The utilization of a new kind of fireplace, wherein it was possible to burn the cheap Ruhr coal grit.

- An application (i.e. in the first Moezel boat and the “Batavia”) to work with forced ventilation.

Finally he studied the construction of a surface-condensor instead of the ordinary injection-condensor, which was not feasible at sea due to the salt forming in the boilers. Making the tubes completely watertight was not succeeding, because of lack of good packing materials. When the rubber was invented making this watertight was successful only, after which it was possible to actually use the surface-condensor and the compound engine on the ocean steaming.